Unipetrol

Westermo switches in critical control networks at Czech petrochemical plant

Application: Power control and monitoring. Emergency shutdown system.

System Integrator: Inelsev

Location: Unipetrol RPA, Czech Republic

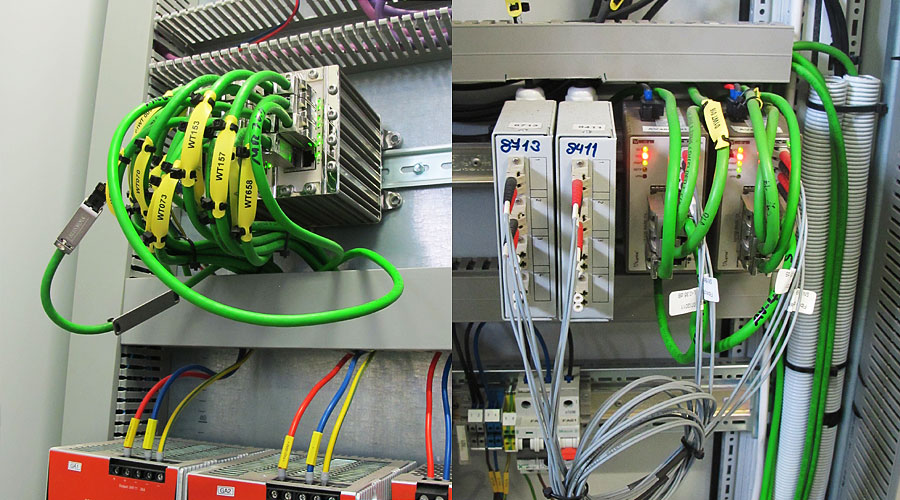

Redfox Industrial and Lynx switches are used to provide reliable data communications for the power control and distribution system and the emergency shutdown system at the Unipetrol RPA plant in the Czech republic.

Unipetrol is a major refinery and petrochemical company in the Czech Republic. One of the company’s biggest assets is the industrial premises Chempark Záluzí which is the largest chemical production facility in the country. The facility is currently the seat of several dozens of important chemical and service companies and is a daily workplace for 6,500 employees from 180 companies.

The part of the plant where Ethylene is produced is particularly important since it is widely used as a component in many other products produced at the plant. A stoppage in the Ethylene production would have enormous economic implications because it would affect the overall production. A complete new network backbone for power control and distribution as well as an upgraded network backbone for the emergency shutdown system has been built with Westermo switches to support the applications in the Ethylene unit.

The communication infrastructure and the systems has been built and implemented by Inelsev, a Czech company that provides services for industrial automation and energetic systems. The decision to use Westermo devices was based on a strong working relationship between Inelsev and Westermo’s Czech distributor.

“This is a plant where reliability is absolutely crucial. The systems are designed to be extremely robust in order to guarantee continuous operation and to protect the plant and the people who work here. In the previous network solution we used another switch brand that we had to replace. The main reason for that was the network ring recovery time. Whenever the network had to recover, it took so long that connected equipment (OPC servers) would not start up and connect properly. WeOS powered Westermo product including the ring network protocol FRNT with 20 ms recovery time was a perfect fit. Extremely fast, robust and easy to use,” said Pavel Ješina, R&D manager at Inelsev who have designed and implemented both networks.

The two networks were built in 2011. The emergency shutdown system was an upgrade project where old switches from another brand were replaced with Westermo Lynx’s in a dual ring network topology. The purpose of this network is to shut down the plant in an emergency situation. The power control and distribution network was built as a completely new system and connects 30 substations throughout the plant with a central control room. The network consists of 270 communication devices, over 500 process screens and panels, 13 000 I/O connections and more than 300 000 alarms. The network consists mainly of Lynx L210-F2G and a variety of RedFox industrial switches.

The many combinations of ports and the possibility to mix copper and fibre media was another big driver for selecting Westermo products. “Inside a building we can use regular copper Ethernet cables, but the cables connecting the different buildings must be fibre due to safety legislations,” explained Pavel. “The many models and port combinations in the RedFox Industrial range allowed us to select the ideal product at every location and to prepare for expanding the network in the future”.

Another positive outcome from using Westermo devices is that configuration and maintenance is extremely simple. All managed Westermo devices are powered by the same operating system, WeOS. This means that you will get an identical experience whether you configure a Lynx, RedFox or any other managed Westermo device, regardless of model. It also means that any new functionality added to any new WeOS version will be backwards compatible and available in any previously installed WeOS device. The operating system is designed to be as robust as the hardware. It is made to be simple to use and configure and thoroughly tested in the Westermo software test lab. “I have worked with many different brands of switches and routers, and compared to many others, configuring a Westermo switch is like kindergarten,” said Pavel.

To make configuration and maintenance even simpler, Westermo also provides WeConfig, a “Made Easy” network configuration management tool designed to simplify both the initial configuration and network commissioning which can be performed much quicker than before and over the lifetime of a network hundreds of man hours can be saved. “I use WeConfig for upgrading the Westermo devices when a new firmware upgrade is made available. The tool makes upgrades simple and hassle free and I can access all units from one central point and automated updates are performed swiftly and securly. I am excited to start experimenting more with WeConfig when we expand our network”, said Pavel.

“We have created a straight forward, robust and reliable network solution. This is exactly what is needed here and the Westermo units have been working flawlessly since they were installed. The products are easy to use and I would not hesitate to select Westermo products for another application where the same type of requirements are needed”, Pavel ends.

Carl de Bruin

International sales

Bitte nutzen Sie für Supportanfragen unser Support Formular